Project 9:

Electric Vehicle Battery Durability and Reliability Under Electric Utility Grid Operations

Objective

Determine the impact of electric vehicle use on battery life including charging cycles and vehicle-to-grid (V2G) applications. The work will identify conditions that improve battery performance and durability. Focus will be placed on providing battery data for system engineering, grid modeling and cost-benefit analysis.

Brief Description

Battery degradation is extremely important to EV technologies and is a function of several factors, such as electrode chemistries, operating temperatures, and usage profiles (i.e. vehicle-only vs. vehicle-to-grid applications). The goal of this research is to assess such impact. Laboratory testing of commercial "18650" Li-ion cells was conducted in Hawaii Natural Energy Institute's Battery Testing laboratory. The battery test plan used two separate experiments: a cycling experiment to assess the impact of both V2G and G2V strategies and a calendar aging experiment to assess the impact of temperature and SOC. The results to date have shown an undeniable impact of V2G, temperature and SOC on the battery capacity loss and indicate that V2G strategies seem to double the capacity loss when performed twice daily. And, if continued at the current pace, the batteries should only last only 36 months before losing 20% of their capacity compared to at least 72 months for cells not participating in V2G. This result is yet to be confirmed by further testing and by modeling.

Research Results

Daily vehicle usage can be broken down into driving, charging and when the car is not in use (idling) periods. In most cases, car batteries spend most of their time not in use and, it is therefore essential to understand the degradation associated with time, temperature and SOC. In order to do so, the researchers performed a literature survey on the impact of calendar aging (i.e. idling), on a selection of battery chemistries representative of the EV market. Additionally, laboratory testing was begun on a batch of commercial Li-ion cells to evaluate the precise impact of temperature and SOC on calendar aging. The work also studied the impact of driving on the cell degradation with or without V2G and G2V periods.

Figure 1. Battery testing laboratory entrance, inside the temperature chamber, temperature chamber and battery tester and a commercial "18650" Li-ion cell used for the UTC project in a battery holder. (Photos: Dr. Arnaud Devie, HNEI)

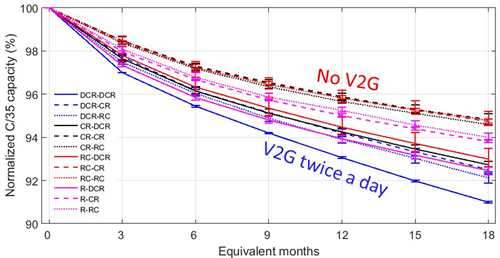

The test plan that uses the "design of experiment" methodology was finalized and detailed in the project's first report in January 2015. It consists of 2 separate experiments: a cycling experiment to assess the impact of V2G and G2V strategies and a calendar aging experiment to assess the impact of temperature and SOC. In order to carry out these experiments, 100 commercial 18650 Li-ion cells were purchased from a retailer and the entire batch was tested for consistency. The results of this initial characterization test were reported in the second report in June 2015. Out of the 100 cells, 36 cells were selected to perform the cycling experiment to assess the impact of both V2G and G2V strategies and as of September 30, 2016, the cells have cycled the equivalent of 550 driving days. Of the remaining 74 cells, 16 were selected for the calendar aging experiment and they have more than a year at their target temperature and SOC. Some observed capacity loss is reported in our third and fourth report. So far, there is an undeniable impact of V2G, temperature and SOC on the capacity loss. Preliminary results indicate that V2G strategies seem to double the capacity loss when performed twice daily (Figure 2) and at the current pace, the batteries should only last only 36 months before losing 20% of their capacity compared to at least 72 months for cells not participating in V2G. G2V (i.e. delayed EV charging) was found to have no impact so far.

Figure 2. Capacity retention under cycle-aging experiment (from report # HNEI-12-16)

High temperature and high SOC were also proven 3 to 4 times more detrimental than lower temperatures and SOC levels.

We started analyzing the degradation in detail to identify whether or not the accelerated degradation observed for the V2G strategy is the same as the normal degradation. Preliminary results seem to indicate that the degradation differs and that V2G usage not only degrades the cell faster but also impacts the negative electrode more intensely. This could have significant impact on the remaining battery life and further reduce the 36 month estimated life and/or prohibit second use for these batteries. This is yet to be confirmed by further testing and by modeling. The remaining 3 months of the project will be devoted to completing the cell analysis and use modeling to forecast their end of life.

Dr. Matthieu Dubarry and his team of researchers at the University of Hawaii have applied for a provisional patent entitled, “Apparatus & Method for Estimating the State of Health of a Battery via Updating the OCV and SOC relationship.” The patent addresses issues with accurately determining the state-of-charge as batteries begin to age.

Impacts/Benefits

Battery degradation is extremely important to EV technologies. Batteries can be sensitive to temperature, SOC and other factors. This raises concerns over battery durability in hot climates. Additionally, with the integration of more and more renewables on the power grid, there is a push to use EV batteries as energy storage systems which may stress the batteries even more. The outcome of this project is to determine the battery stress levels and to identify potential mitigation measures to extend battery life and improve performance.

Reports

Dubarry, M., Truchot, C., Devie, A., Liaw, BY. "State-of-Charge Determination in

Lithium-Ion Battery Packs Based on Two-Point Measurements in Life"

Journal of Electromechanical Society, 162 (6) A877-A884 (2015).

Dubarry, M., (2015). Test Plan to Assess Electric Vehicle Cell Degradation under Electric Utility Grid Operations (HNEI Pro. No. HNEI-03-15). Honolulu, HI: Hawaii Natural Energy Institute, University of Hawaii at Manoa.

Dubarry, M. and Devie, A., (2015). Initial Conditioning Characterization Test and Other Preliminary Testing (HNEI Pro. No. HNEI-06-15). Honolulu, HI: Hawaii Natural Energy Institute, University of Hawaii at Manoa.

Dubarry, M. and Devie, A., (2016). Cell Emulation and Preliminary Results (HNEI Pro. No. HNEI-11-16). Honolulu, HI: Hawaii Natural Energy Institute, University of Hawaii at Manoa.

Dubarry, M. and Devie, A., (2016). Battery cycling and Calendar Aging: Year One Testing Results (HNEI Pro. No. HNEI-12-16). Honolulu, HI: Hawaii Natural Energy Institute, University of Hawaii at Manoa.

Devie, A. and Dubarry, M. Durability and Reliability of Electric Vehicle Batteries under Electric Utility Grid Operations. Part 1: Cell-to-Cell Variations and Preliminary Testing, Batteries, 2016, 2(3), 28 doi:10.3390/batteries2030028

Dubarry, M., Devie, A. and McKenzie, K., ”Durability and Reliability of Electric Vehicle Batteries under Electric Utility Grid Operations: Bidirectional Charging Impact Analysis”, Journal of Power Sources, 358 39-49, (2017).

Dubarry, M., Devie, A. “Methods and Apparatus for Updating a Fuel Gauge and Estimating State of Health of an Energy Storage Cell,” US Publication 15/444.163 filed February 27, 2017.

Dubarry, M., "Electric Vehicle Battery Durability and Reliability Under Electric Utility Grid

Operations", Hawaii Natural Energy Institute, University of Hawaii at Manoa (HI-18-17), Florida Solar Energy Center Report No. FSEC-CR-2064-17. May 2017.

Project Title: University: Principal Investigator: Matthieu Dubarry PI Contact Information: Funding Source:Research and Innovative Technology Administration Total Project Cost: Agency ID or Contract Number: Start date: End date: |