Project 6:

Electric Vehicle Life Cycle Cost Analysis

Objective

Compare total life cycle costs of electric vehicles, plug-in hybrid electric vehicles, hybrid electric vehicles, and compare with internal combustion engine vehicles. The analysis will consider both capital and operating costs in order to present an accurate assessment of lifetime ownership costs. The analysis will include vehicle charging scenarios of photovoltaic (solar electric) powered charging and workplace charging.

Brief Description

This project compared total life cycle costs of battery electric vehicles (BEV), plug-in hybrid electric vehicles (PHEV), hybrid electric vehicles (HEV), and vehicles with internal combustion engines (ICE). The analysis considered capital and operating costs in order to present an equal comparison of differing vehicles. The analysis also included photovoltaic (PV) and workplace charging options. The overall goal was to define the total cost of ownership over 5, 10, 15, and 20 year life expectancies. The developed computer program and report completes this project effort.

Research Results

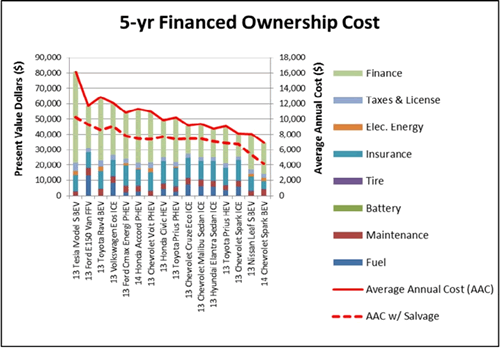

This report had three objectives: to develop a life cycle cost (LCC) model for automotive vehicles that accurately evaluates electric vehicle types, to allow for any user to download and use the developed LCC model, and to evaluate photovoltaics (PV) as a power option for electric vehicles. The most important part of the work is the LCC model that compared ownership costs, on a present value and an annual cost basis, of plug-in hybrid electric vehicles (PHEV) and battery electric vehicles (BEV) as compared to conventional internal combustion engine (ICE) vehicles for an average number of miles driven per year. The analysis used actual cost values for 16 production vehicles all sold in the United States. The LCC model includes the vehicle costs of purchase price with federal incentives, if any, salvage value, fuel consumption (electricity and liquid fuel), tires, insurance, maintenance, state tax and financed interest payments. The vehicles considered are hybrid electric vehicles, PHEVs, and BEVs as compared to ICEs using gasoline, ethanol, or diesel. It is noted that the traction battery replacement costs for electric vehicles are difficult to ascertain, yet they are included in the analysis by replacing the batteries in the 11th year in order to investigate the battery impact on overall costs. Economic factors used in the LCC include differing rates for inflation, discount, and fuel escalation and battery degradation in the electric vehicles to account for battery energy depletion over time. The LCC was performed over a 5-, 10-, or 15-year lifetime period.

For the specific case of 12,330 miles driven per year and for the selected economic factors, the LCC results show that even with higher first costs, battery powered vehicles are lower in cost to conventional ICE vehicles. Using the two lowest-cost variant vehicles, a Nissan Leaf and a Hyundai Elantra, the Leaf's 5-year annual cost including salvage value is $5,360/year compared to the Hyundai at $7,076/year. The results for the 10-year lifetime show the Leaf at $4,683/year and the Hyundai at $6,040/year. These results are primarily due to lower fuel cost of electricity versus gasoline, which for the Leaf is $3,919 while the Hyundai gasoline cost is $10,931 for the 10-year period. A comparison of two other popular plug-in electric vehicles, the Chevrolet Volt and Toyota Prius, shows higher values for both vehicles; over a period of 10 years, the Volt is $6,286/year and the Prius is $6,156/year.

The results for the case where the government incentive of $7,500 is deleted also show the LCC values for a Leaf over a 10-year period is less than the Hyundai when salvage value is considered. The Leaf is $5,369/year compared to the Hyundai at $6,040/year. For a 5-year period, this result is also true where the Leaf is $6,733/year and the Hyundai is $7,076/year.

Figure 1. 5-Year Financed Ownership Cost

Impacts/Benefits

The results provide consumers with the requisite information needed to make an informed financial decision regarding the purchase of personal transportation. Although electric vehicle technology is higher in first cost, the operating and maintenance cost savings provide lower life cycle costs than conventional vehicles (for those vehicles that are reasonably priced). The analysis also shows that a PV system of about 4 kW in size would supply the required electrical energy for an EV traveling the yearly miles assumed.

Reports

Raustad, R., Fairey, P. (2014). Electric Vehicle Life Cycle Costs Assessment. Electric Vehicle Transportation Center, FSEC-CR-1984-14.

Fenton, J. (2015). “PV, EV, and Your Home at Less Than $1 a Gallon.” The Electrochemical Society Interface. Spring 2016. DOI: 10.1149/2.F01151IF.

Raustad, R. (2017). Electric Vehicle Life Cycle Cost Analysis (FSEC Rep No. FSEC-CR-2053-17). Florida Solar Energy Center: Cocoa, FL.

Project Title: University: Principal Investigator: PI Contact Information: Florida Solar Energy Center Funding Source: Total Project Cost: Agency ID or Contract Number: Start date: End date:

|